Arnold Packaging was founded in 1933 as Arnold’s Factory Supplies, a manufacturer of adhesives and inks used for packaging applications. Fast forward 85 years, and the Baltimore-based company has become a comprehensive supplier to the packaging industry with the forward-thinking vision of Mick Arnold. In their 80,000-square-foot facility, production personnel manufacture custom packaging and containers for large enterprises.

Business Challenge

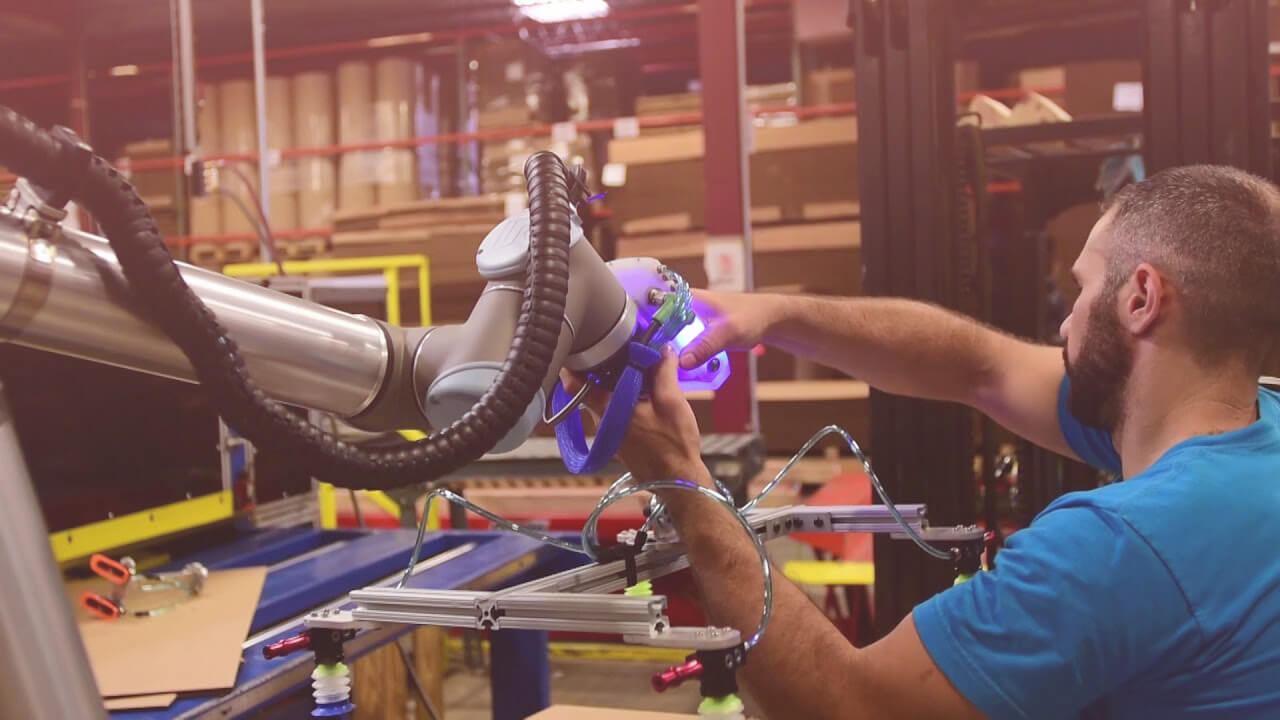

Arnold’s process starts with the collection of custom specifications for an order and communicating them to the production floor. From there, technicians work together to complete the various tasks in a workflow before the deliver-by date.

Prior to using FactoryFour, activity was recorded manually on time sheets, so managers lacked real-time visibility on operations. Arnold had a tedious, manual process of understanding data that couldn’t keep up with the pace of the production floor.

Arnold Packaging needed a solution that would provide advanced production visibility, so that they could enhance technician productivity and gain significant managerial time savings.

“Gaining clear visibility into production is the rising tide that lifts all boats. Productivity increases with accountability, and time savings increase capacity. FactoryFour introduced advanced visibility without disrupting our day-to-day processes.”

Colin Jesien | VP & General Manager

Our Solution

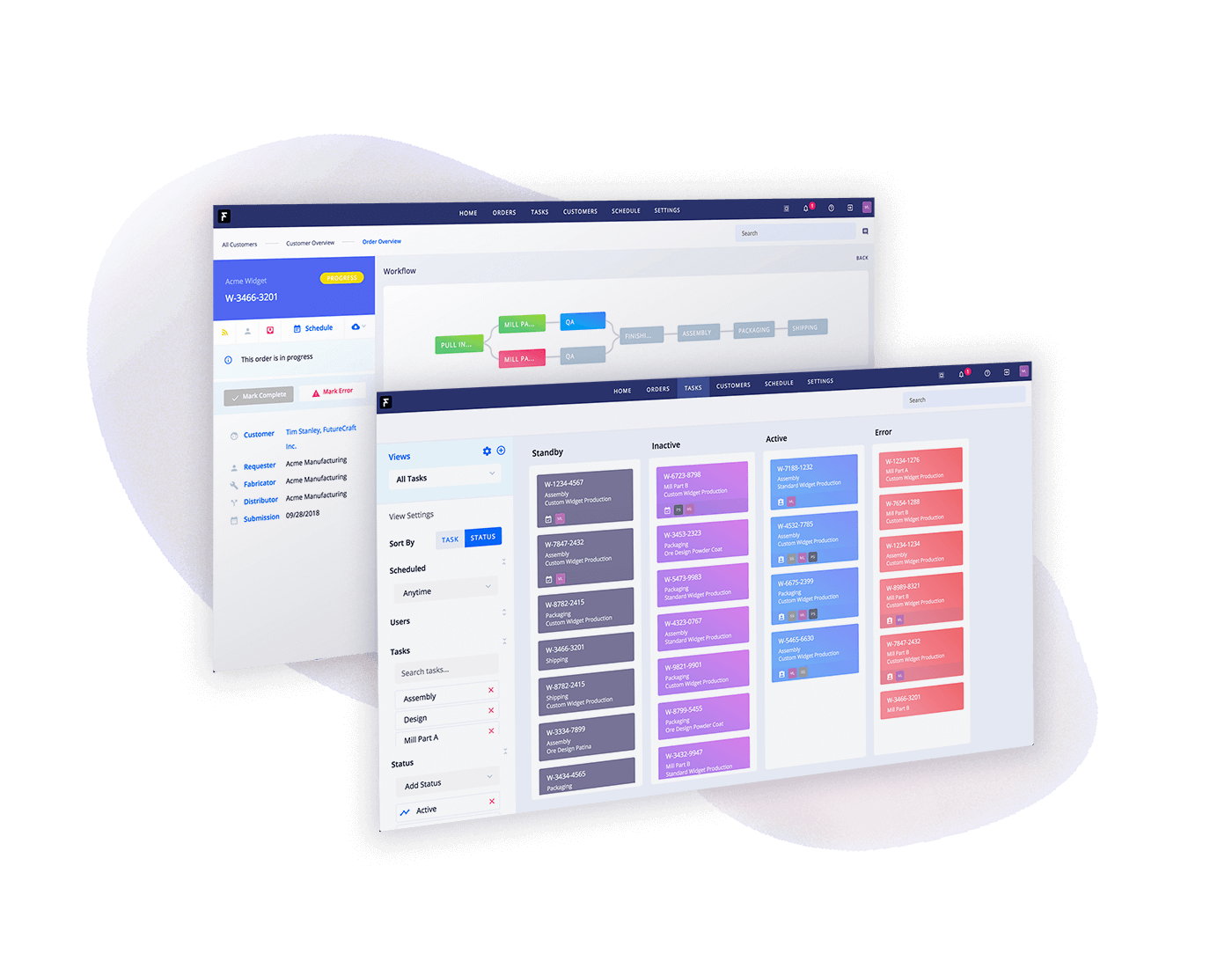

WithDashboards in FactoryFour, Arnold Packaging significantly increased visibility into their production process, gaining insights on production in real time as opposed to the end of the week.

Through a seamless integration with Arnold’s Epicor system, orders and their specifications are automatically collected by FactoryFour to initiate production. From there, technicians use tablets stationed throughout the production floor to check in and out of tasks they are assigned to. The integration allows Arnold to optimize the production floor without disrupting front-office processes.

While technicians are completing each task, FactoryFour automatically collects data on every event that occurs. Arnold’s managers are able to monitor order status in real time, and can easily access overarching insights such as the number of man-hours required to complete a particular product.

“FactoryFour is the only solution that allows me to get deep visibility on my unique processes. I can trust the true metrics they provide to help drive continuous improvements.”

Mick Arnold | CEO

Advanced, real-time production visibility.

Arnold recreated their complex workflows in FactoryFour using our simple drag-and-drop interface. Technicians use tablets stationed around the production floor to scan barcodes associated with each work order. They then check in and out of each task as the work order moves from station to station. Managers can view the progress of each order in real time on the floor, and can get automatic status notifications using custom rules.

Powerful insights with data analytics.

As technicians move work orders along the production floor, FactoryFour automatically gathers data on task completion, technician activity, and more. Arnold configured custom dashboards to monitor metrics such as:

-

Number of man-hours spent on each work order and task.

-

Average time to complete each task.

-

Outstanding work orders in each station.

-

Number of orders completed per day.

-

Productivity of individual technicians.

Seamless improvement without disruption.

Arnold uses Epicor ERP to enter production orders and manage inventory. To seamlessly transfer production order data into FactoryFour, we used our API to integrate with Epicor. Data is pulled every 2 minutes, so technicians can stay updated on orders from the floor. In addition, we are able to capture critical order information and allow for data enrichment by providing support for uploading CAD files and other data points. Our complete integration with Epicor enabled Arnold to adopt the FactoryFour platform without disrupting existing front-office processes or charging implementation fees.

In the Future

Arnold Packaging wants to take their partnership with FactoryFour even further by extending the platform to their sales team. Sales personnel will be able to submit quotes directly from the field, allowing production to begin as soon as an order is placed. As Arnold Packaging’s business grows, they’ll be able to add more automation to their processes via the FactoryFour platform, streamlining production even further.

Ready to integrate advanced production visibility into your business?

Join the Waitlist

Download the Customer Story