Comprehensive Prosthetics & Orthotics (CPO) is one of the largest orthotic and prosthetic service providers in the US. They receive orders to manufacture medical devices from their own network of brick-and-mortar clinics, which span across Illinois, Iowa, Indiana, and Missouri. Hundreds of their clinicians submit orders to two central fabrication facilities, in which they manufacture each product custom to their patients’ needs.

Business Challenge

Before FactoryFour, CPO’s clinicians sent plaster casts and clay impressions of patients' limbs along with paper forms to their central fabrication facilities. Often, the ordering process involved several back-and-forth calls to rectify errors or clarify details in the order submission. Order data was then manually transcribed, and issued to the floor as a paper work order. During production, a job traveler moved through each work center, and technicians referenced the paper work order to produce each custom product.

Whenever a customer called with an order inquiry, it required a tedious process of going to the floor, locating the job traveler, and relaying the order status back to the customer. CPO needed a solution that would connect their clinics directly to the manufacturing floor, providing immediate visibility for customers and managers while streamlining the process for their technicians.

“It was crucial for us to find a production management solution that seamlessly handled order processing as well. Receiving calls from customers asking where orders are is an expensive inefficiency that we've eliminated.”

Chaitanya Pampana | Vice President

Our Solution

With FactoryFour, CPO saved 20 minutes of labor in producing each medical device by streamlining order flow from their network of clinics to their manufacturing facilities, while increasing supply chain transparency through greater visibility into production.

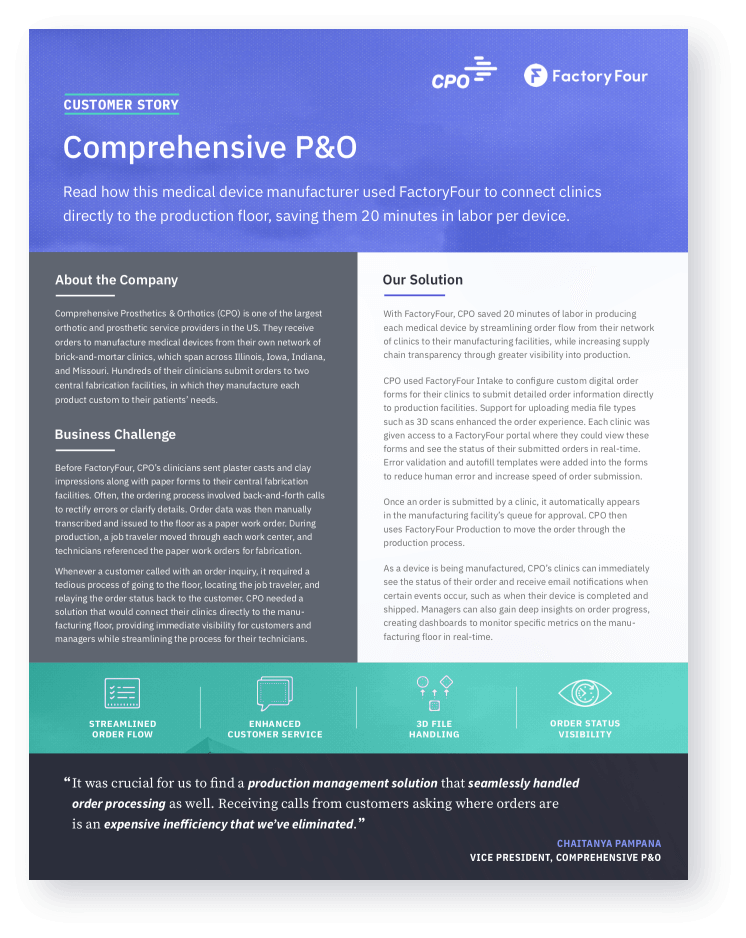

CPO usedForms in FactoryFourto configure custom digital order forms for their clinics to submit detailed order information directly to production facilities. Support for uploading media file types such as 3D scans enhanced the order experience. Each clinic was given access to a FactoryFour portal where they could view these forms and see the status of their submitted orders in real time. Error validation and autofill templates were added into the forms to reduce human error and increase speed of order submission.

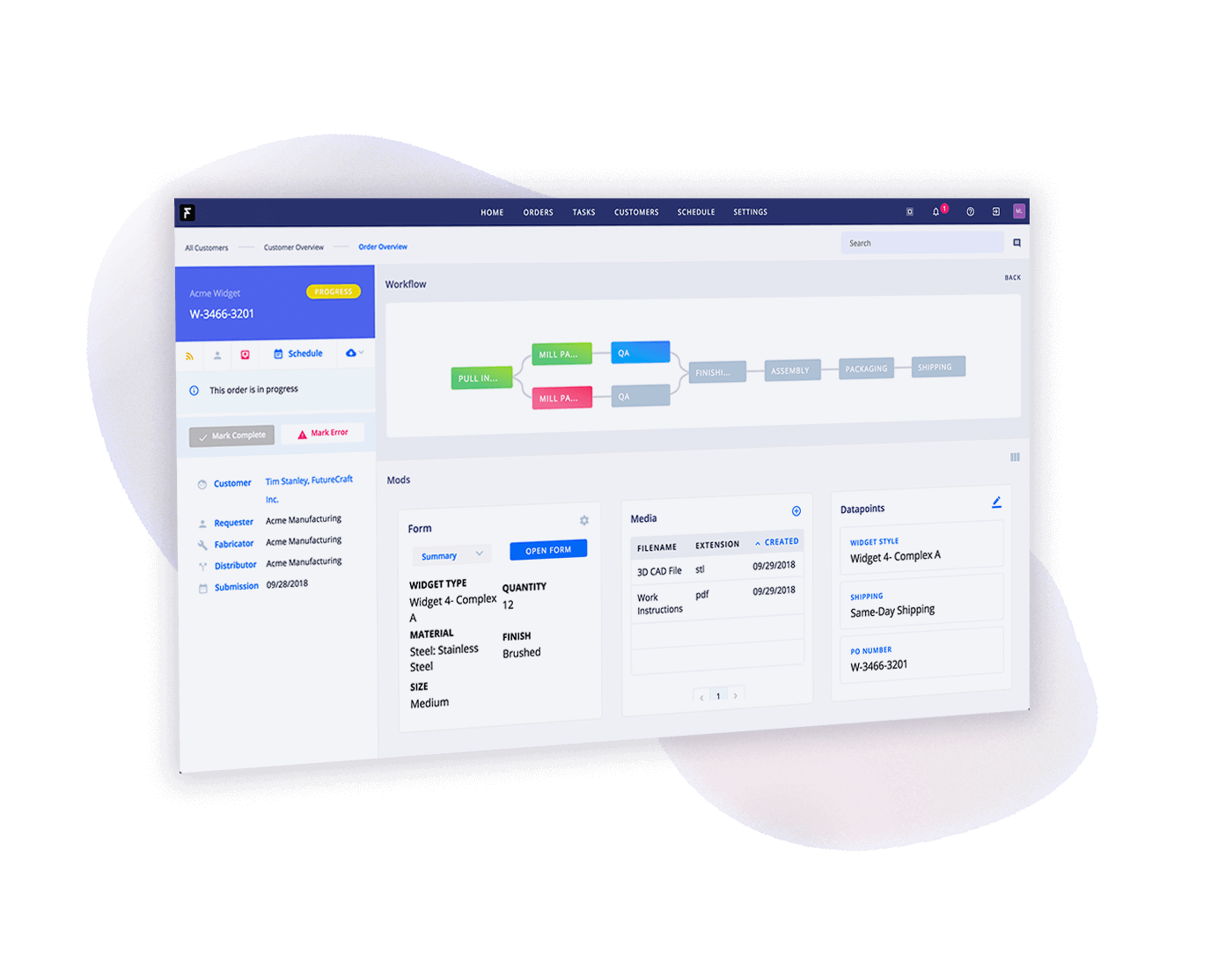

Once an order is submitted by a clinic, it automatically appears in the manufacturing facility’s queue for approval. CPO then usesWorkflows in FactoryFourto move the order through the production process. Tablets fixed at each station notify technicians of the tasks they have been assigned to, which include milling, thermoforming, and shipping.

As a device is being manufactured, CPO’s clinics can immediately see the status of their order and receive email notifications when certain events occur, such as when their device is completed and shipped. Managers can also gain deep insights on order progress, creating dashboards to monitor specific metrics on the manufacturing floor in real time.

“We've tried other software to manage our production, but quickly switched to FactoryFour after seeing the real-time data management and the ease of deployment.”

Amit Bhanti | CEO

Seamless order-to-production flow.

CPO used FactoryFour to create a streamlined workflow of processing orders and tracking them through production. Orders were previously submitted in various forms ranging from paper to email, and errors often occurred during processing. Now, CPO’s network of clinics submit orders digitally via customized forms, that automatically validate for errors before reaching the manufacturing floor. During production, the order enters a workflow configured in FactoryFour, which notifies technicians of the next step to complete at each station.

Real-time dashboards for production management.

CPO’s managers needed greater control over production, and FactoryFour delivered through real-time dashboards that monitored the progress of each order. These dashboards were configured to provide metrics such as:

-

Number of outstanding work orders from each clinic.

-

Productivity of individual technicians.

-

Number of active work orders at each station.

-

Turnaround time for each order from date received to shipped.

Improved transparency with order status visibility.

Before FactoryFour, phone tag between clinicians and the manufacturing floor was a time-consuming daily activity. Now, as technicians complete tasks to manufacture each device, clinicians are provided with real-time visibility on their orders. CPO configured automatic email notifications to be sent to clinicians by FactoryFour when certain events occur, such as when an order is shipped. With the FactoryFour portal, clinicians receive full visibility with real-time order status, and have a way to directly message fabrication facilities.

In the Future

CPO will continue to expand integration of FactoryFour throughout its network, making more products available for digital ordering. In their manufacturing facilities, they will be implementing barcode scanning equipment to make recording production activities easy and instantaneous.

Ready to streamline order flow in your business?

Join the Waitlist

Download the Customer Story